Case History - Z-Axis Stoppage on EDM

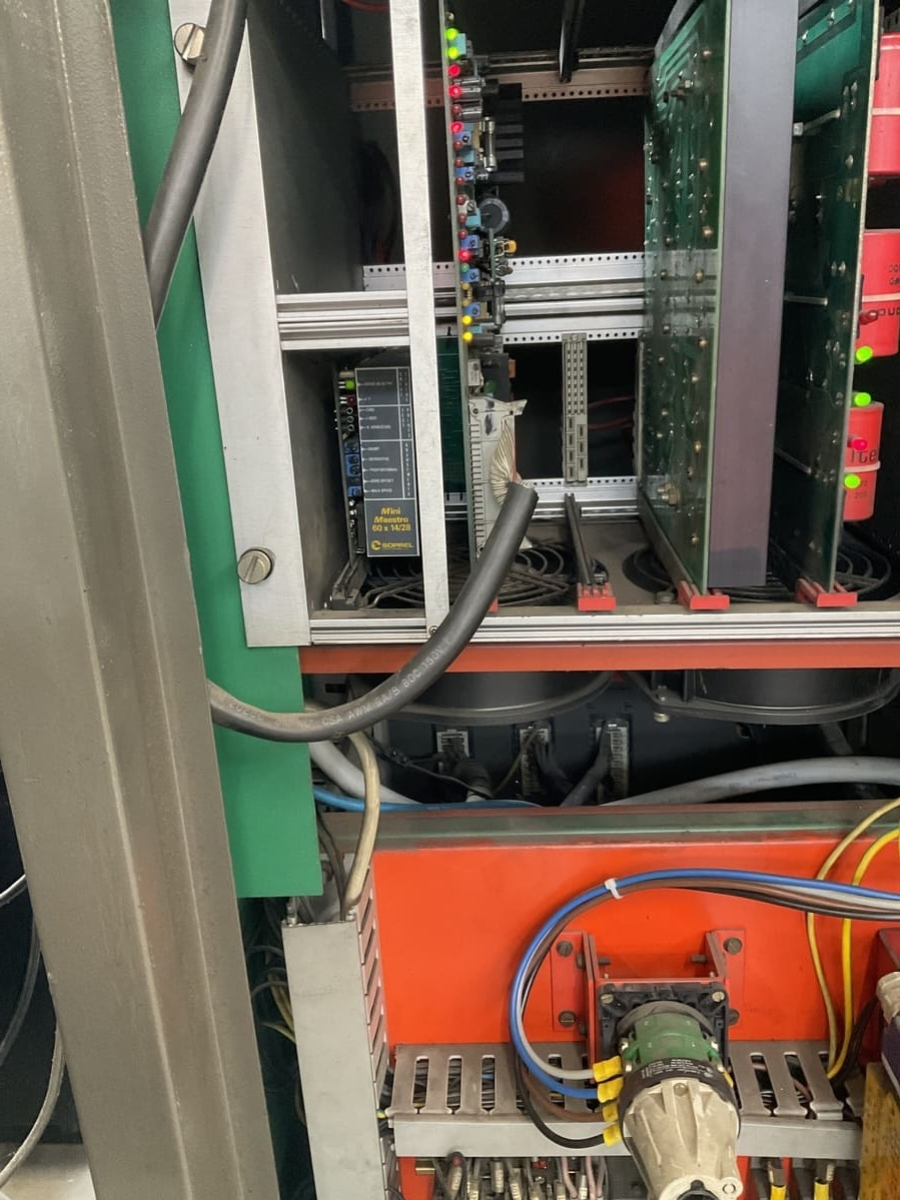

Restoration of Die-Sinking EDM with Issues on the Z Axis

The problem: Z-axis blockage on CNC machine for electrical discharge machining

One of our clients contacted us regarding a serious failure on a CNC die-sinking EDM machine. The Z-axis of the machine, after completing the probing cycle, returned to the limit switch in the upper position (positive direction) and subsequently became completely stuck, preventing any operation.

Diagnosis and Technical Intervention

The technical team at Dama Service CNC, specialized in CNC services and maintenance on machine tools, followed a structured analysis procedure:

- Initial checks for short circuits and measurements of supply voltages

- Problem identification: the servo board, although powered, was non-operational

- Removal and shipment of the board to specialized suppliers for repair

- After reinstalling the repaired board, the Z-axis movement issue persisted

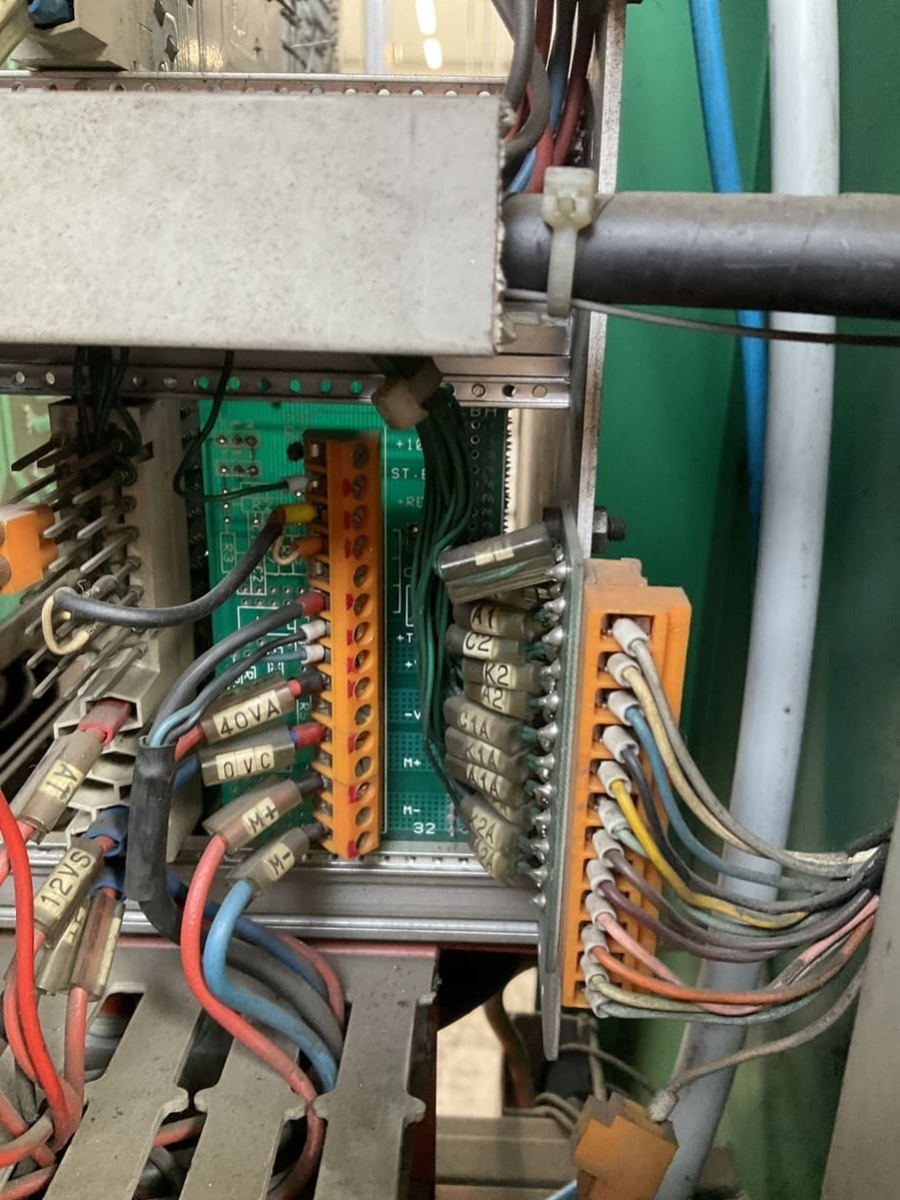

- In-depth analysis of the control boards and verification of the command voltage up to the motor terminal block

- Motor inspection revealed damaged brushes: one completely worn out and the other destroyed

- Specialized motor repair and full reinstallation

- Thorough functional and erosion testing to verify the machine's full operability

Result: CNC machine back in operation

Thanks to a prompt and skilled intervention, the machine was restored to full operation. Final tests confirmed the success of the operation and the stability of the system.

This CNC repair allowed the client to resume production without further issues or delays.

Why is CNC maintenance essential?

This case highlights the fundamental importance of preventive maintenance, especially on machines with significant service age.

Numerical control machines are precise and powerful tools, but they require regular maintenance to operate at full capacity.

In this case, the failure was due to wear of internal components that, if checked earlier, would have prevented the breakdown. This is why preventive maintenance is a true investment: it avoids costly machine downtime and ensures production continuity.

The advantage of relying on Dama Service CNC

Thanks to our specialized experience in CNC machine tool service and in-depth knowledge of electrical discharge machining systems, we were able to identify and resolve a complex issue involving several critical system components, quickly restoring the client's machine to full operation.

Accurate and tailored diagnostics and repairs for your CNC

Thanks to our CNC support, we intervene promptly to resolve anomalies and failures. Our comprehensive CNC repair service immediately restores your machine's efficiency.

Discover the CNC fault repair serviceRequest information

For more information about our services or to request assistance, we invite you to contact us.

You will receive a prompt response from one of our experts.